Post by john larkinPost by boBOn Thu, 11 Apr 2024 06:54:47 -0700, John Larkin

Post by John LarkinOn Thu, 11 Apr 2024 09:13:26 +0200, Klaus Vestergaard Kragelund

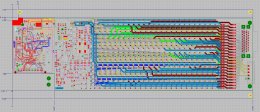

Post by Klaus Vestergaard KragelundPost by John Larkinhttps://www.dropbox.com/scl/fi/fiy73ou127rd5hi23jkw9/P948_A6.jpg?rlkey=symijy4b0veq1s5ho982r0sa0&raw=1

My layout guy is struggling with this. Actually, he seems to be

enjoying it.

It has two D25 connectors, 130 relays, 49 polyfuses, and the usual

FPGA and such. 8 layers, four of which will be 2oz copper.

It's a big PCB for sure.

Yes. It is supported on the ends.

https://www.dropbox.com/scl/fi/43dl9eoja8gr0j0wqox56/P940_FA_2.jpg?rlkey=n3s4ycq3cpnxwx7d6l8jbxm50&dl=0

One customer wants to fly it and is rightly concerned about vibration.

I'm working on that.

The Brat put up our new web site yesterday, and it includes the public

announcement of our modular power system.

https://www.highlandtechnology.com/Category/MPS

The P940 system originated when a customer, on a zoom call, said "we

hate power supplies."

Post by Klaus Vestergaard KragelundNasty layout program, looks like it's from the 90'ties

It has pads and traces. Don't all layout programs do that?

It's PADS. We've been using it since the dos/floppy disk days. It

works fine. I don't like the color scheme that my guy uses; we change

the colors before we release the boards.

The schematic editor is excellent. It actually understands

connections.

Very pretty with all those layers/colors !

Just put enough standoffs to hold it and should be fine.

Be careful of big ceramic SMT caps next to flex points.

boB

It's supported on the ends and is very flexy.

My plan is to add rubber weatherstripping strips to the chassis bottom

and to and top cover, to damp resonances.

This feels good, nice and snug.

https://www.dropbox.com/scl/fi/gifrf8h2j3ldnlv8azfsv/BWS_in_P940_chassis.jpg?rlkey=9mfy323fj2l0gr579c2ockfic&raw=1

https://www.dropbox.com/scl/fi/u9u5zb7wq22y6vvuh2isf/BWS_D_on_cover.jpg?rlkey=ynwn6yt3maeh094q8uyd48g9n&raw=1

This will go in a "flying test bed", basically an old 747 with three

original engines and one DUT. Vibration will be mild, nothing like an

F35.

Even so, beware. Those cards _will_ flex badly, and destroy the card

to card connectors first. Fretting, maybe fracture. Depends. The

card may be OK, but it too will fail eventually. BTDT. Or rather, I

got the fixup job, in the 1970s.

Later, I've seen fretting due to cooling-fan vibration and tin-plated

connector fingers destroy a midi-computer in the 1990s. Which is why

people don't use tin plated connectors (even with some anti-whisker

lead alloyed in) in such applications.

The two bumper weather strips don't look to be enough, especially when

the top and bottom sheets flex outward. But edge clamps screwed to

those sheets could work. Or some kind of crossbars passing between

the circuit cards from top sheet to bottom sheet.

Joe Gwinn